Sacrificial Anodes

Glass lining is never 100% perfect. It always has "holidays", unprotected steel surface area. Therefore, it is a general industry practice the use of anodes. Industrial equipments such as: hot water tanks, water heaters, boilers and fire trucks may have anodes installed.

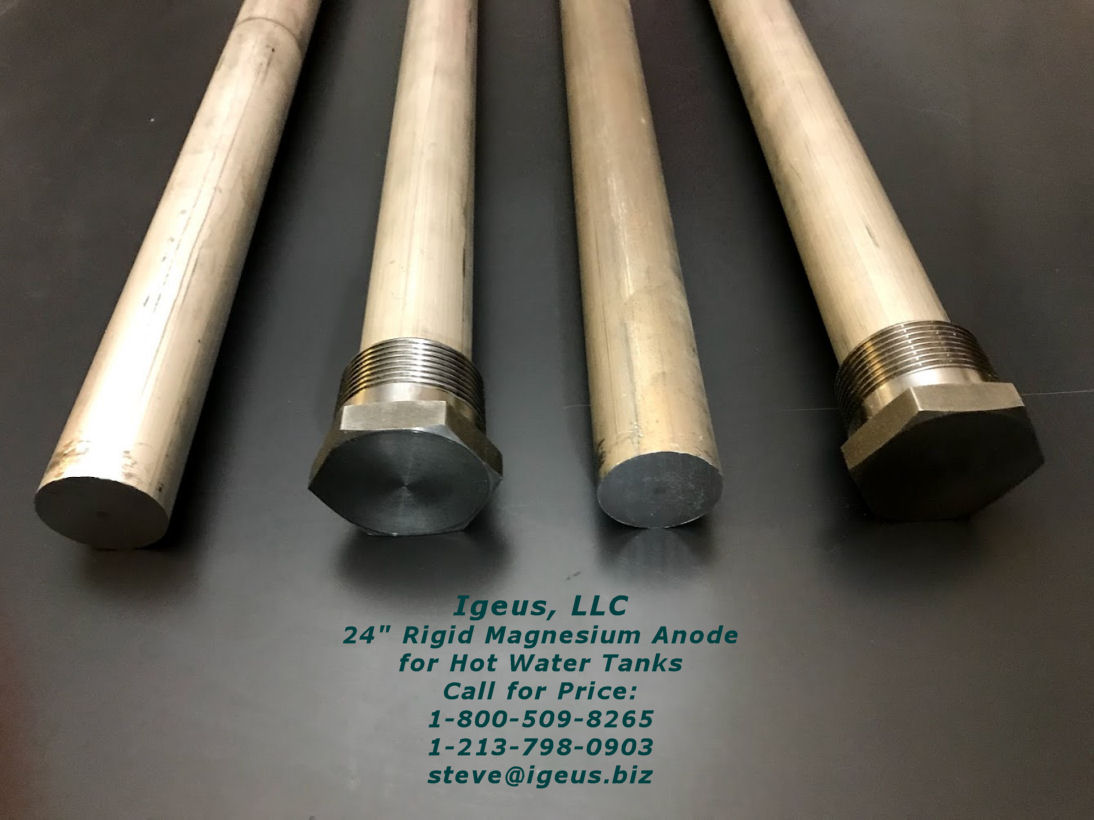

Sacrificial anodes are protecting the steel from rusting. It can be made from magnesium or aluminum or other metals electro-chemically more reactive than steel. Our anodes are made from magnesium.

We supply "rigid" and "flex" anodes. Rigid anodes usually installed in a horizontal position on the side of the tank. Flex anodes are installed in vertical position hanging from the top of the tank. They require at least 12" clearance above the vessel. Flex anodes are preferable because it could reduce the annual maintenance cost drastically. The maintenance person does not need to drain the tank, just depressurize it and pull the old anode out and inspect it and replace it if it is corroded. If the vessel has rigid anodes on the side of the tank then the maintenance person needs to drain the tank below the anode connections which will cost time and money. Anodes are mandatory on a glass lined tank. It is optional on a cement lined tank and it is an absolutely NO on epoxy lined tanks because it will cause blistering of the epoxy.

Please call us @ +1-213-798-0903 or email: contact@igeus.biz for price.